Vespel® does not outgas or melt at any temperature & performs well in vacuum applications, even in extremely low cryogenic temperatures.

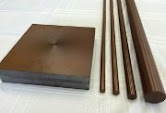

Vespel® polyimide is available in five standard grades:

Vespel® SP-1 - Unfilled. Maximum strength & elongation. Lowest modulus & thermal conductivity. Optimum electrical properties.

Vespel® SP-21 - 15% graphite (by weight). Enhances inherent wear resistance, improves long term thermal stability.

Vespel® SP-22 - 40% graphite (by weight). Gives low coefficient of thermal expansion. Maximum creep resistance.

Vespel® SP-211 - 15% graphite and 10% TEFLON® fluorocarbon resin (by weight). Lowest static friction.

Vespel® SP-3 - 15% MoS2 (by weight). Best wear performance in dry environments.

Vespel® SP-21 - 15% graphite (by weight). Enhances inherent wear resistance, improves long term thermal stability.

Vespel® SP-22 - 40% graphite (by weight). Gives low coefficient of thermal expansion. Maximum creep resistance.

Vespel® SP-211 - 15% graphite and 10% TEFLON® fluorocarbon resin (by weight). Lowest static friction.

Vespel® SP-3 - 15% MoS2 (by weight). Best wear performance in dry environments.

For the full-range of Vespel products, visit https://www.professionalplastics.com/Vespel or call (888) 995-7767.

No comments:

Post a Comment